A Pneumatic PET Strapping Tool with with public praise-How to Save Thousands of dollars for you

With the popularity of packaging, more and more factories and enterprises need to package their products. Portable packaging machines are loved by more and more people.Portable Packing Machines mainly include Manual Packing Machines, Pneumatic Packing Machines and Electric Packing Machines.

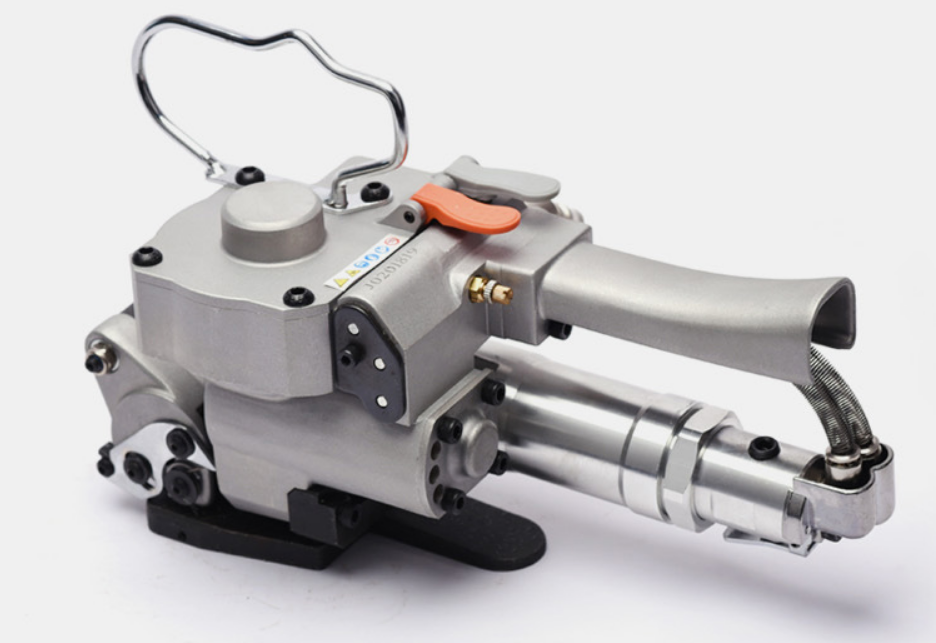

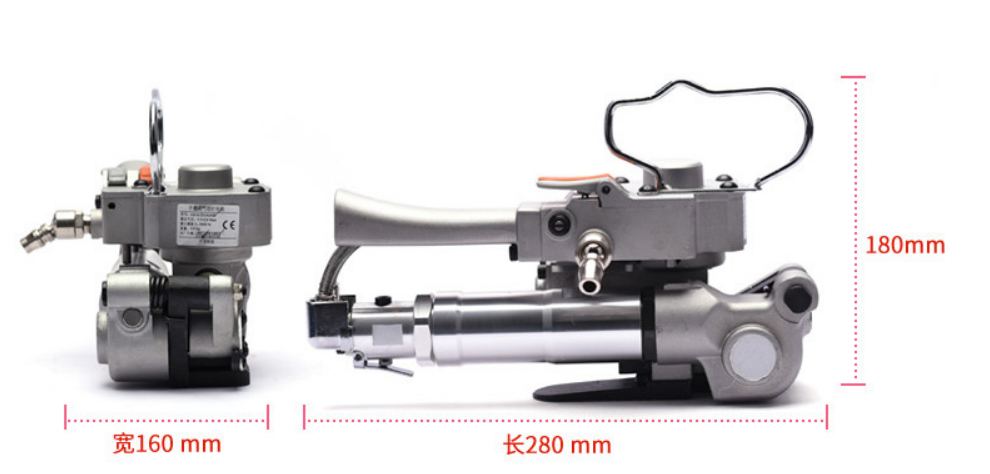

Both the Pneumatic Packing Machines and the Electric Packing Machines have the functions of one button tightening, welding and strap cutting.Among them, CA19/25 Pneumatic Packing Machines has become a popular model with strong tightening force and low failure rate.

What is the reason why it is favored by the majority of users? Let’s take a look at the advantages:

- 1.Wide range of applicable environments

It has attracted much attention because of its convenient carrying, simple operation and durability. It is suitable for harsh factory environment, such as brick factory, stone, wood-based panel factory, non-ferrous metal and other industries. It does not need to have requirements for the packaging environment like the electric packaging machine.

- 2.Simple design, hard shell

It adopts high-strength lightweight aluminum alloy body design, streamlined appearance design of the shell, simple but generous and low-key luxury from the inside to the outside. The whole machine is about 3.8kg, lightweight and portable, with high hardness and wear resistance, which greatly improves the working efficiency and service life of the packer.

- 3.Affordable, energy saving and environmental protection

In general, the price of the Pneumatic Packing Machines is lower than that of the Electric Packing Machines. It does not need power supply. It is driven by the whole process air source. The tension and vibration motors are separated. It has strong power and low failure rate. It can be packed 24 hours a day. The whole packaging process can be completed in just 10 seconds by tightening the buckle and cutting the strap with one key operation.

- 4.High speed adjustment of large tension

The high-speed vibration friction hot-melt interface has a large tightening force, the maximum tightening force can reach 3500N, the seal connection can be completed in 3 seconds, and the packaging cost can be saved by 30% compared with the packaging seal connection. The high-strength tempered anti-skid tightening structure, the secondary tempering of the tensioning wheel and the stop slider can reach 60, and the strength and wear resistance can be increased by 40%. The packing machine is equipped with a loose band valve rod, which can be removed as required.

In general, CA19/25 Pneumatic Packing Machine welds the interface of PET plastic steel strap through friction hot melting of PET plastic steel strap. It has the advantages of low failure rate, low maintenance cost, large pulling force and strong continuous operation ability. It is especially suitable for the packaging of heavy goods. On the one hand, it can ensure the packaging effect, on the other hand, it can effectively improve the packaging efficiency and save manual packaging costs.